Microcomputer temperature controller

First of all, thank you for purchasing our company's microcomputer temperature controller. This product brings together a wide range of modern heating and cooling technologies, with the advantages of small size, simple operation, accurate temperature measurement and strong anti-interference ability. It is suitable for most users to use various automatic and intelligent control systems for various refrigeration and heating equipment in different environments. The cooling and heating modes can be set through menus and have the function of setting parameters and power-off permanent memory.

Technical Parameters:

1. The working voltage is referenced on the product casing;

2. -40°C ~120°C: Measurement error ± 0. 5 ° C

3. -40°C~120°C: Temperature control accuracy: 1°C display accuracy 0. 1°C

4. NTC25°C=10K B3435 1% soil (1 meter long, regardless of positive or negative)

5. Power supply voltage: DC12~72V

6. Working environment: Temperature: -20 ° C ~ 70 ° C, humidity: 90% RH no condensation

7. Product size: 75*85*35 (width, depth and height) mm

Instructions:

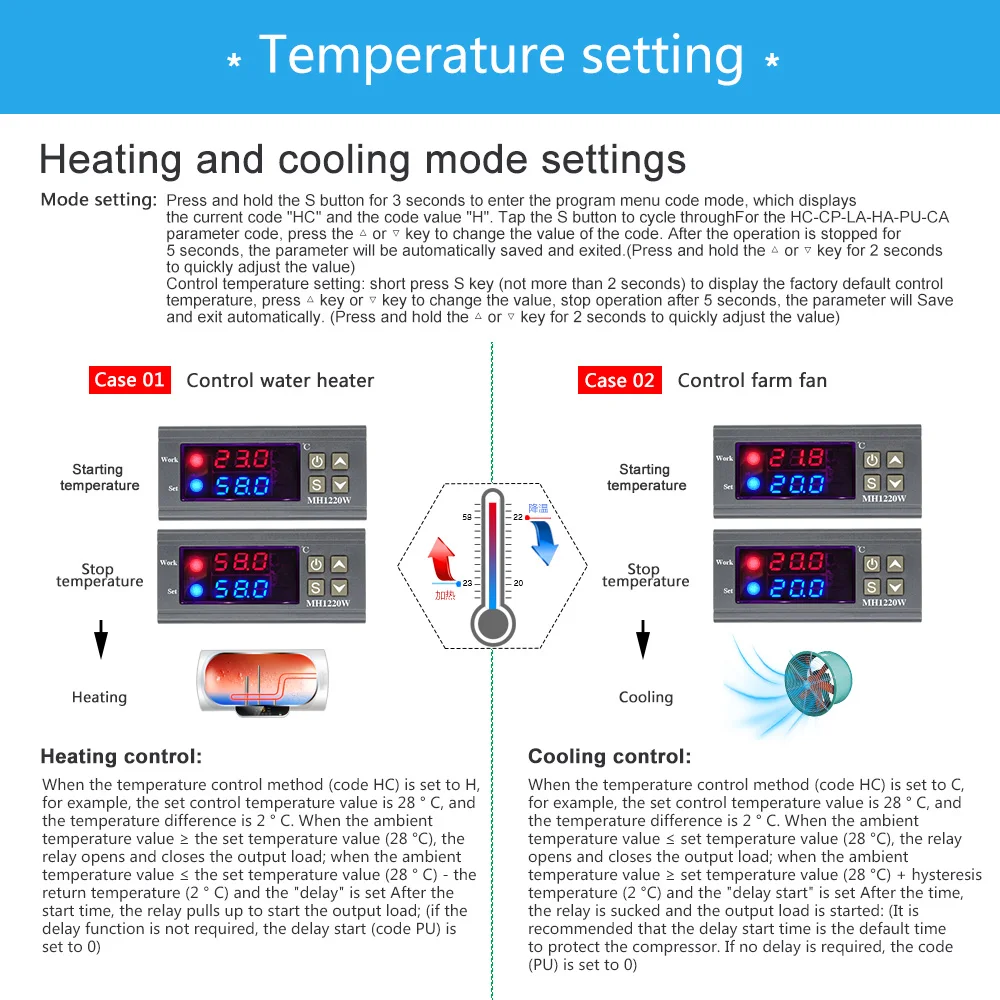

Mode setting: Press and hold the S key for 3 seconds to enter the program menu code mode, which displays the current code "HC" and the code value "H". Press the S key to cycle through the HC-CP-LA-HA-PU-CA parameter code. Press the △ or ▽ key to change the value of the code. After the operation is stopped for 5 seconds, the parameter will be automatically saved and exited. (Press and hold the △ or ▽ key for 2 seconds to quickly adjust the value)

Control temperature setting: Short press S key (not more than 2 seconds) to display the factory default control temperature. Press △ or ▽ key to change the value. After 5 seconds of stop operation, the parameters will be saved automatically and exited. (Press and hold the △ or ▽ key for 2 seconds to quickly adjust the value)

Heating control:

When the temperature control method (code HC) is set to H, for example, the set control temperature value is 28 ° C, and the temperature difference is 2 ° C. When the ambient temperature value ≥ the set temperature value (28 °C), the relay opens and closes the output load; when the ambient temperature value ≤ the set temperature value (28 ° C) - the return temperature (2 ° C) and the "delay" is set After the start time, the relay pulls up to start the output load; (if the delay function is not needed, the delay start (code PU) can be set to 0)

Cooling mode:

When the temperature control method (code HC) is set to C, for example, the set control temperature value is 28 ° C, and the temperature difference is 2 ° C. When the ambient temperature value ≤ set temperature value (28 °C), the relay opens and closes the output load; when the ambient temperature value ≥ set temperature value (28 °C) + hysteresis temperature (2 °C) and the "delay start" is set After the time, the relay is sucked and the output load is started: (It is recommended that the delay start time is the default time to protect the compressor. If no delay is required, the code (PU) is set to 0)

Menu Code Table: Code:

| Code | Function | Set Range | Default |

| HC | Heating/Cooling | H/C | H |

| CP | Return Difference | 1-30 | 2 |

| HA | Setting limits to the manimum | 120 | 120 |

| LA | Setting limits to the minimum | -40 | -40 |

| P4 | Temp. Correction | -10-10 | 0 |

| PU | Delay Start | 0-10min | 0 |

Power button instructions:

1 Press and hold the power button for 3 seconds to turn off, press and hold the power button for 3 seconds to turn it on again.

2 In the control temperature setting interface and mode setting interface, short press the power button to quickly save the settings and exit the setting interface.

Restore factory default: After pressing the △ and ▽ keys for 5 seconds at the same time, all the set parameters of the user will be restored to the factory defaults.

Parameter lock: Press and hold the ▽ button for 3 seconds and release the hand to display “0FF” to indicate that the user has set the parameter to be locked. In this way, the same operation flashes “ON” to indicate that the user has set the parameter lock to be released. (The user can only view and cannot modify after the parameter is locked, but the control degree adjustment is still valid)

When the sensor is short-circuited or when the ambient temperature is detected above the upper temperature limit of 120 degrees, the flashing indicates that the HHH well closes the output load. When the sensor is open or detects that the ambient temperature is below the lower temperature limit of -40 degrees, the LLL is flashed and the output load is turned off.

1. In order to prevent high-frequency interference, the sensing time line during installation cannot be bundled with the power line and the load device line, and separate wiring is required.

2. The power supply and the host marked voltage must be consistent, the rated voltage value deviation is not more than 1% 0%, the sensor is strictly distinguished from the sensor, power line and load output interface.

3. The thermostat main unit cannot be installed in places where dripping water, old people, and children are within easy reach.

4. After wiring, check whether the line is correct and then energize, so as to avoid accidentally burning the temperature controller and load equipment. After installation, apply the protective cover to cover.

Installation wiring diagram